Lithium-ion battery lug welding process mainly ultrasonic welding and laser welding, welding quality is directly related to the overall performance of lithium batteries, yield, and battery life.

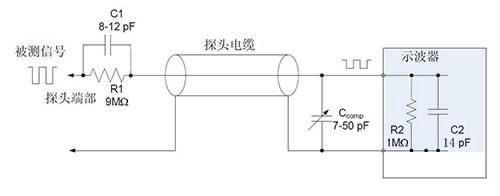

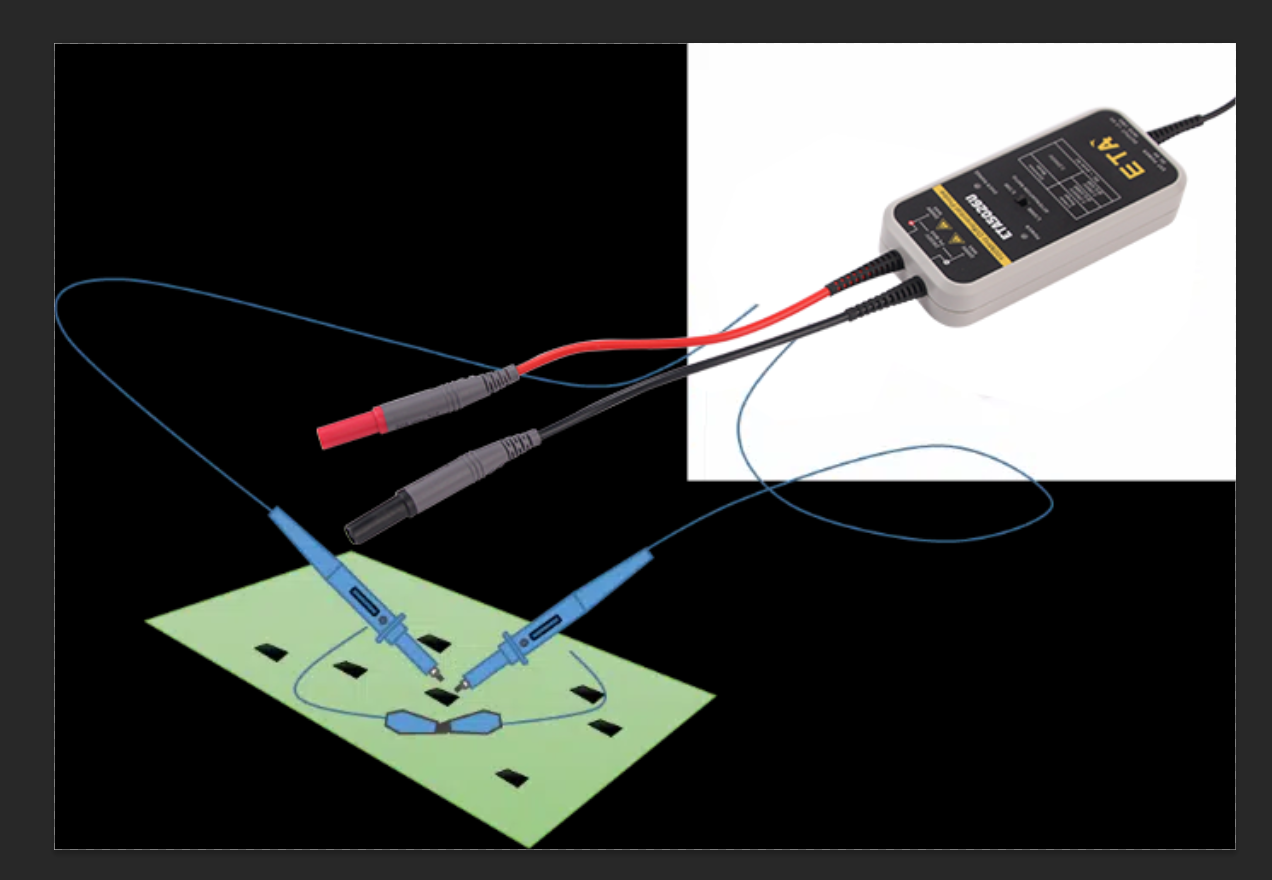

Schematic diagram of lug welding station

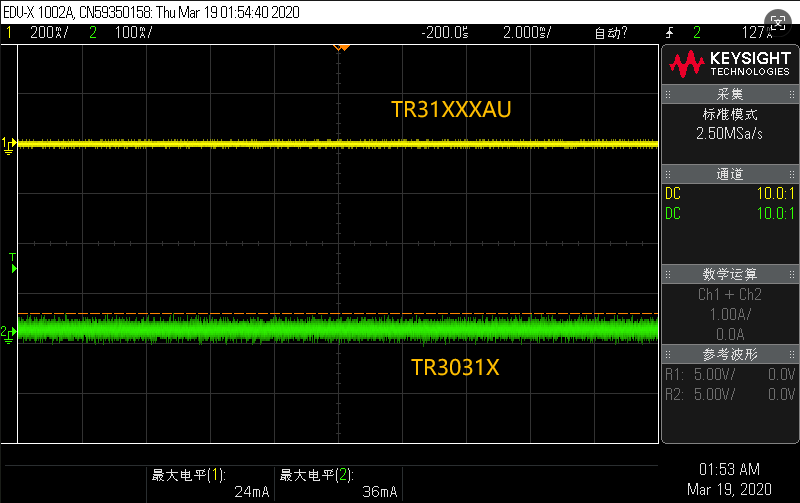

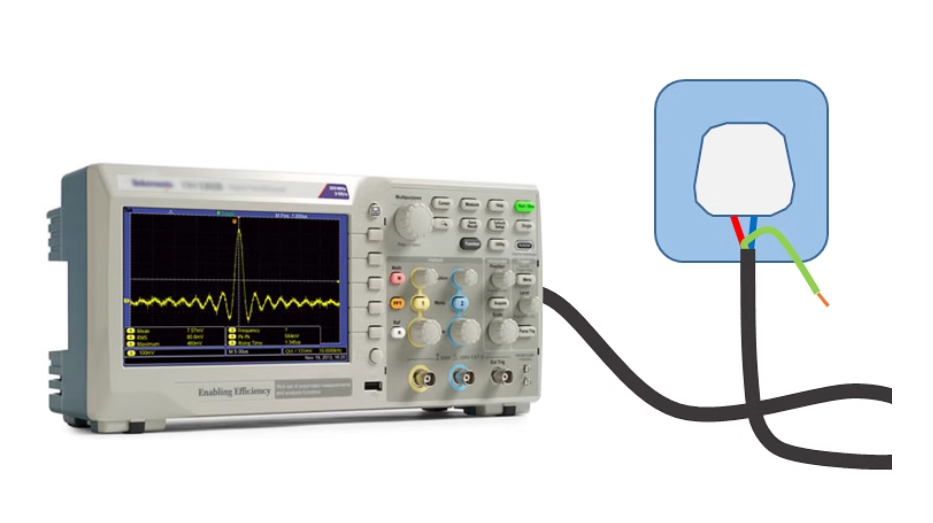

After actual measurement, the contact resistance after lug welding is usually around 10 to 100 microohms, depending on the electrode material, when the micro-resistance meter measures the high resistance value, it can be used to screen the abnormal batteries and improve the automation production efficiency. In fact, not only lug welding, the type of battery busbar, you can also use the micro-resistance meter to check the contact resistance after welding. For example, pole ear false welding, leakage welding, pole ear misalignment, etc., can use the micro-resistance meter RM3545 to check the pole ear welding resistance, to help find and confirm the bad welding situation.