In the field of electrical measurement, the current clamp has become an indispensable tool for engineers and technicians because of its characteristics of safe measurement without cutting off the circuit. However, many users tend to overlook its core component-the jaw. As everyone knows, the state and operation mode of the jaw directly determine the accuracy and reliability of the measurement data. Just as precision instruments need to be carefully adjusted, the correct use and maintenance of current clamp jaws is also the first link to obtain accurate measurement results.

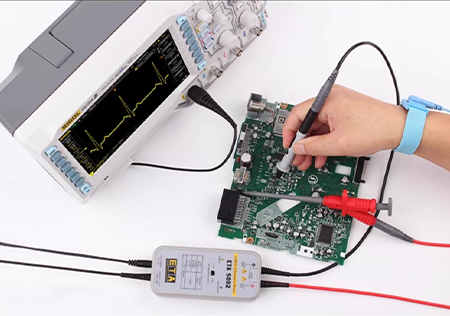

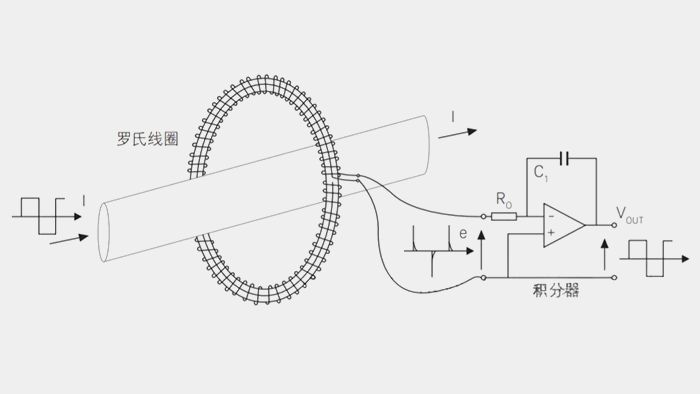

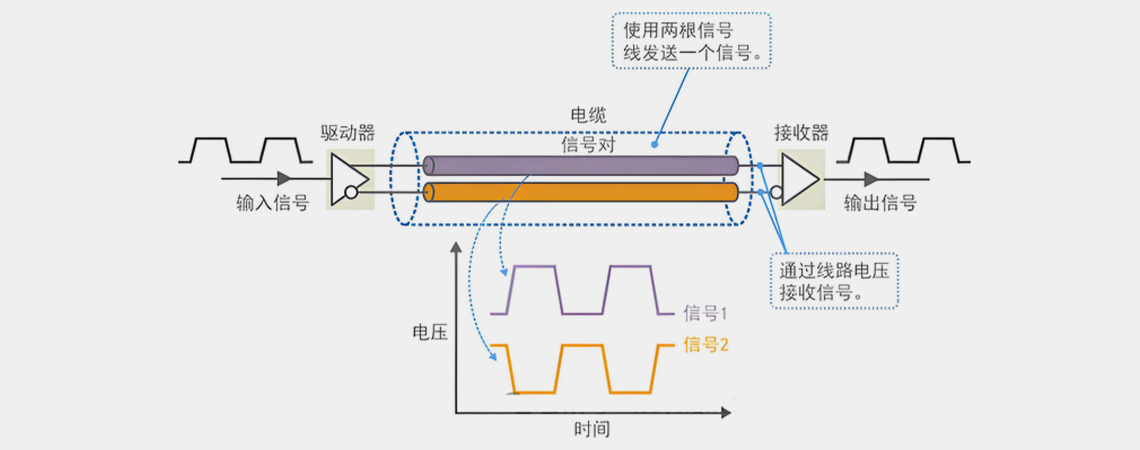

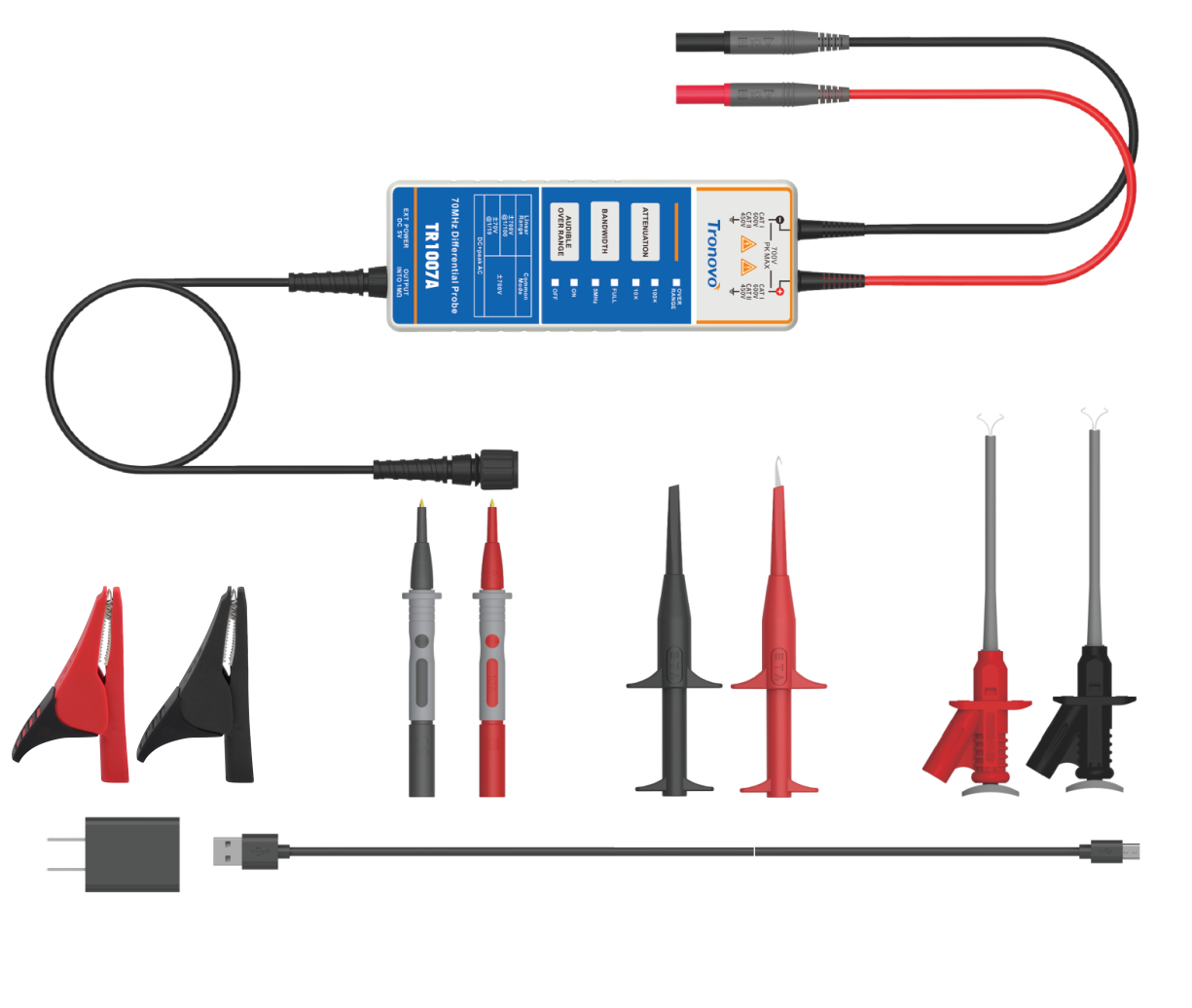

The measuring principle of the current clamp fundamentally determines the key position of the jaw. Whether it is an AC clamp meter based on the principle of a current transformer or an AC/DC clamp meter using the Hall effect, it relies on the jaws to form a complete magnetic circuit or to achieve accurate induction of the magnetic field. In actual operation, first of all, it is necessary to ensure that the jaws are completely closed: any slight non-contact or oil and dust on the contact surface may form an air gap, increase the magnetic resistance, cause magnetic flux leakage, and eventually lead to a significantly lower measured value. At the same time, the position of the wire is also very critical-the single wire should be perpendicular to the jaw plane and centered as much as possible. Any offset or tilt may disrupt the symmetric distribution of the magnetic field, introducing additional errors.

In addition to the standard operation, the daily maintenance of the jaws is also crucial. Clean the contact surface regularly with a soft cloth dipped in a small amount of alcohol to remove oil and dust; avoid mechanical impact or excessive force causing jaw deformation or magnetic core damage; after use, it should be reset in time and stored in the protective sleeve to prevent the contact surface from oxidation or physical collision. For precision measurement applications, it is recommended to regularly send the equipment to a professional organization for calibration, especially after experiencing severe temperature changes or mechanical vibration, it is necessary to check the closing accuracy and measurement linearity of the jaws.

It is worth noting that in different measurement scenarios, the use of jaws also has its own points. When measuring large current, it is necessary to ensure that the rated capacity of the jaw is not exceeded to prevent the magnetic core from saturating and distorting the reading. Before high-precision measurement, the equipment should be allowed to stand in the measurement environment for sufficient time to make its temperature reach a stable state. In strong interference environment, data reliability can be improved by averaging multiple measurements.

Mastering the correct use and maintenance method of the current clamp jaw can not only ensure the accuracy of the measurement data, but also extend the life of the equipment and improve the work efficiency. Behind every accurate measurement comes from the adherence to details and the care of tools. Let's start with the correct use of jaws and move towards more professional and accurate measurement practices.